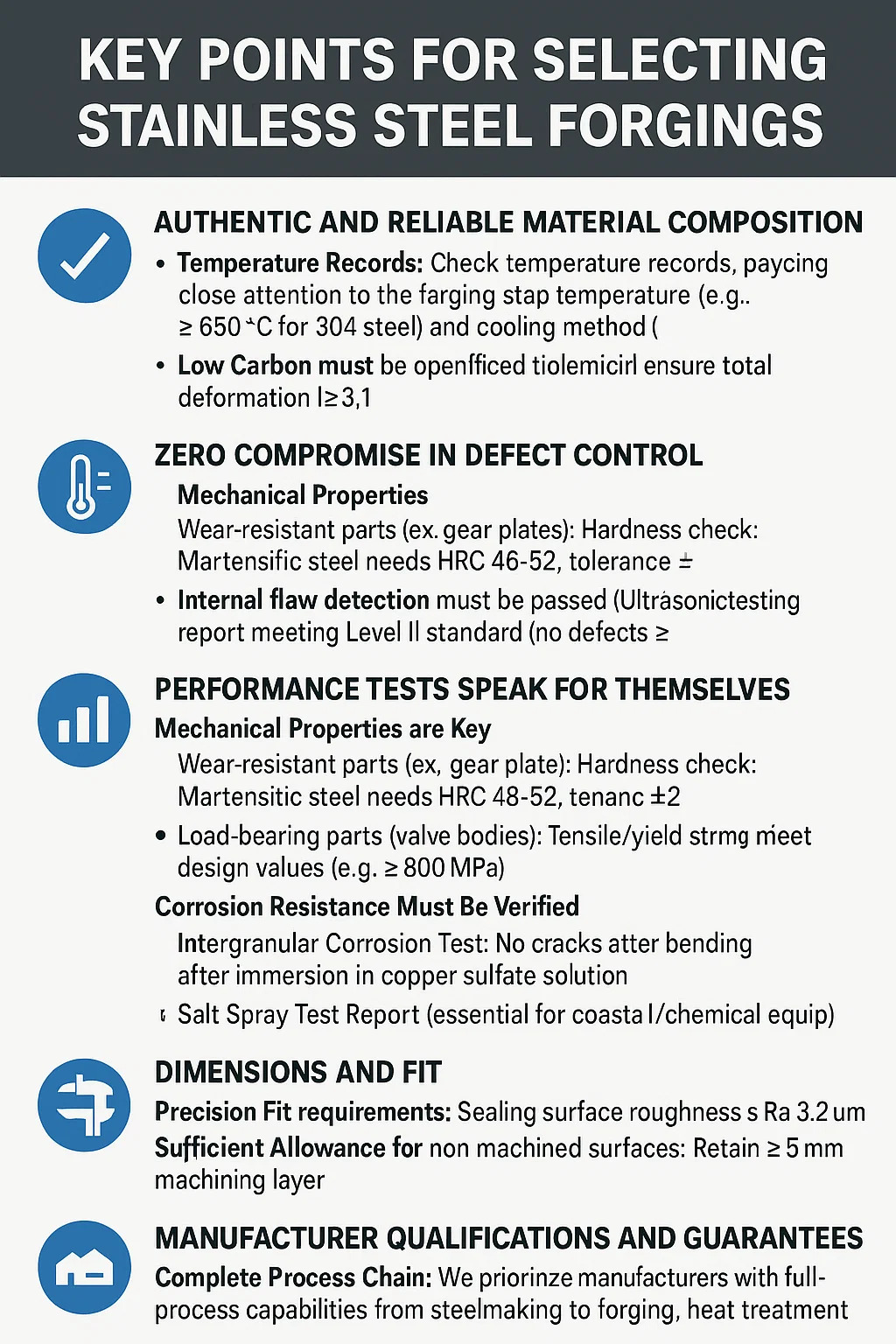

Key Points for Selecting Stainless Steel Forgings

1. Authentic and Reliable Material Composition

Key Elements Must Be Secured: Confirm that the chromium (Cr), nickel (Ni), and molybdenum (Mo) content meets the grade requirements (e.g., 316L requires ≥2% molybdenum). Request a smelting report from the manufacturer; reject "approximately meeting" standards.

Low Carbon is a Must: Ultra-low carbon steel (e.g., 304L) must have a carbon content ≤0.03% to prevent intergranular corrosion.

2. Transparent and Traceable Forging Process

Temperature Records Must Be Checked: Request heating curves, paying close attention to the forging stop temperature (e.g., ≥850℃ for 304 steel) and cooling method (water quenching/slow cooling).

Forging Ratio Must Be Sufficient: Total deformation must be ≥3:1 to ensure a dense internal structure (metallographic verification can be requested).

3. Zero Compromise in Defect Control

Smooth and Unblemished Surface: No cracks or folds visible to the naked eye; uniform bright white color after pickling, without black spots or rust.

Internal flaw detection passed: Ultrasonic testing report meets Level II standard (no defects φ>2mm), especially high-pressure components require 100% inspection.

4. Performance Tests Speak for Themselves

Mechanical Properties are Key:

Wear-resistant parts (e.g., gear plates): Hardness check: Martensitic steel needs HRC 48-52, tolerance ±2.

Load-bearing parts (e.g., valve bodies): Tensile/yield strength must meet design values (e.g., ≥800MPa).

Corrosion Resistance Must Be Verified:

Intergranular Corrosion Test: No cracks after bending after immersion in copper sulfate solution.

Salt Spray Test Report (essential for coastal/chemical equipment).

5. Dimensions and Fit

Precision Fit Requirements:

Sealing surface roughness ≤ Ra 3.2μm (leakage prevention).

Assembly position tolerances controlled according to h7/H7 (avoid on-site grinding).

Sufficient Allowance for Non-machined Surfaces: Retain a ≥3mm machining layer to ensure defects can be removed.

6. Manufacturer Qualifications and Guarantees

Complete Process Chain: We prioritize manufacturers with full-process capabilities from steelmaking to forging, heat treatment, and testing.

Clear Traceability Marking: Permanent stamps on forgings must include the grade, furnace number, and heat treatment batch number (all are mandatory).

Speed After-Sales Response: A written commitment to respond to quality issues within 48 hours to prevent production line downtime.

英语

英语 德语

德语 阿拉伯语

阿拉伯语