Content

- 1 What is Forged Alloy Steel?

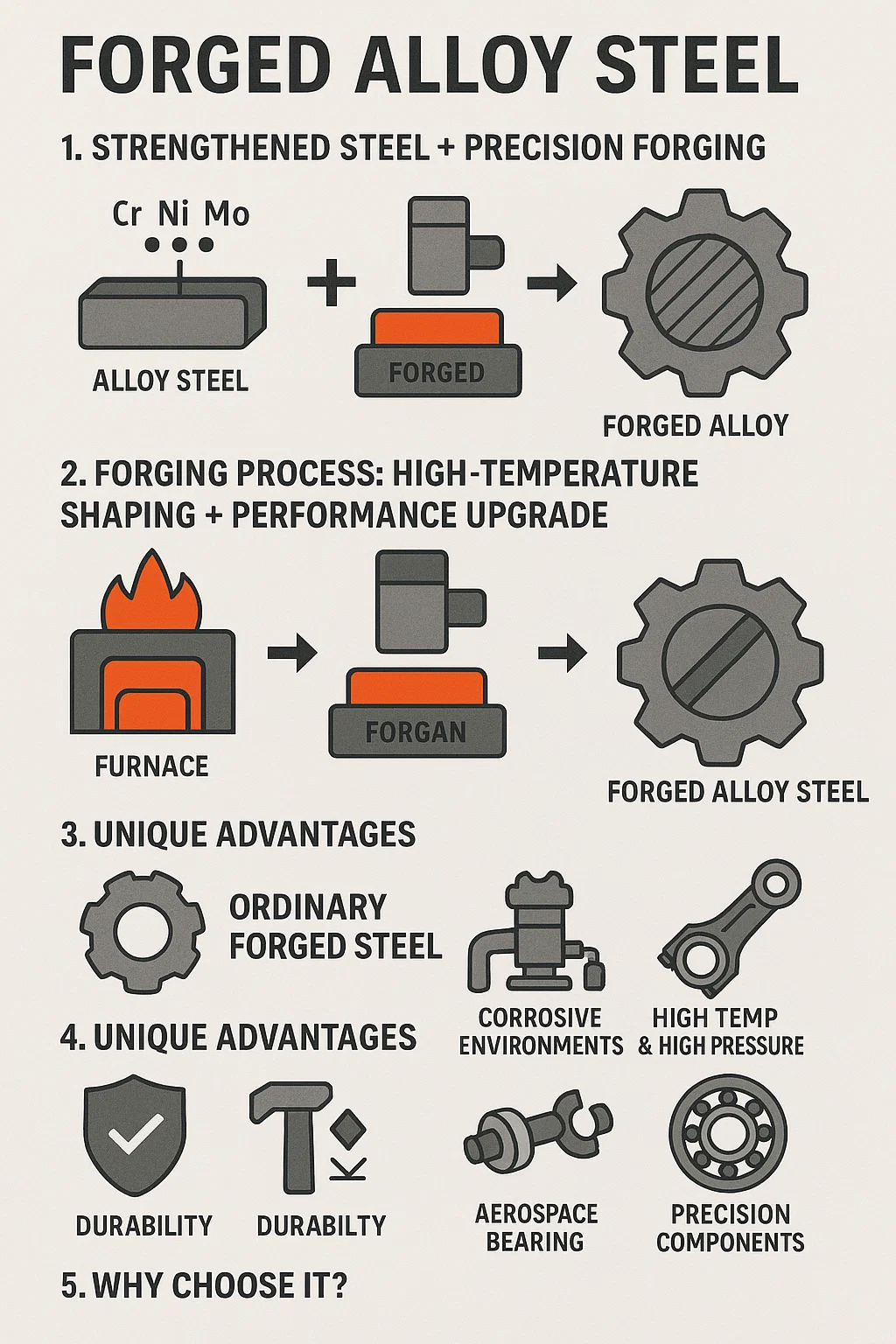

- 1.1 1. Essentially, it's "Strengthened Steel + Precision Forging"

- 1.2 2. Forging Process: High-Temperature Shaping + Performance Upgrade

- 1.3 3. Unique Advantages: What ordinary steel can't do, it can!

- 1.4 4. Typical Applications: Specifically for Tough Work:

- 1.5 5. Why Choose It? More Cost-Effective in the Long Run!

What is Forged Alloy Steel?

1. Essentially, it's "Strengthened Steel + Precision Forging"

Alloy steel: "Strengthening elements" (such as chromium for rust prevention, nickel for toughening, and molybdenum for heat resistance) are added to ordinary carbon steel, essentially giving the steel "skill points."

Forging: The alloy steel billet is heated to a high temperature (approximately 1100℃) and repeatedly hammered into shape (similar to a blacksmith's forging).

Combined Effect: A well-formulated strengthening formula followed by forging and compaction—performance is doubled, far surpassing cast or directly machined parts.

2. Forging Process: High-Temperature Shaping + Performance Upgrade

Heating and Softening: The alloy steel billet is heated to an orange-red color in the furnace, softening and becoming easily deformable.

Heavy Hammer Compaction: High-speed hammering achieves two key functions:

▶Eliminating Defects: Breaking up air bubbles and shrinking cavities, making the interior as dense as a solid block of iron.

▶Directional Strengthening: Grains extend along the direction of stress, forming "metallic flow lines" (like wood grain), significantly increasing impact resistance.

Heat Treatment for Fixed Properties: Subsequent quenching and tempering adjust properties (e.g., making it harder or tougher).

3. Unique Advantages: What ordinary steel can't do, it can!

Advantages of Ordinary Forged Steel vs. Forged Alloy Steel:

General Strength and Toughness: Resistant to heavy pressure and impact (core components of mining machinery)

Prone to Rust/Wear: Rust-proof, wear-resistant, and high-temperature resistant (addition of alloying elements)

Thick parts have weak core performance: Strong and tough from the outside in (superior hardenability)

Shorter lifespan: Doubled durability (reduced downtime for replacement)

4. Typical Applications: Specifically for Tough Work:

High-Intensity Operations: Crusher hammers, excavator teeth—relying on high hardness and impact resistance to break through ore.

Corrosive Environments: Chemical pumps and valves, offshore drilling parts—rust and corrosion resistant (e.g., 316L stainless steel forgings).

High Temperature and High Pressure: Engine crankshafts, power plant valves – do not soften at high temperatures, do not crack under high pressure.

Precision Components: Aerospace bearings, automotive connecting rods – combine strength and toughness with lightweight design.

5. Why Choose It? More Cost-Effective in the Long Run!

Save on Maintenance Costs: Wear-resistant and durable, extended lifespan → fewer spare parts replacements.

Safe and Reliable: Fatigue-resistant and fracture-resistant, reducing the risk of accidents (e.g., high-pressure valves do not burst).

Flexible Design: Can be made lighter and thinner while maintaining the same strength (e.g., weight reduction in racing car connecting rods).

英语

英语 德语

德语 阿拉伯语

阿拉伯语