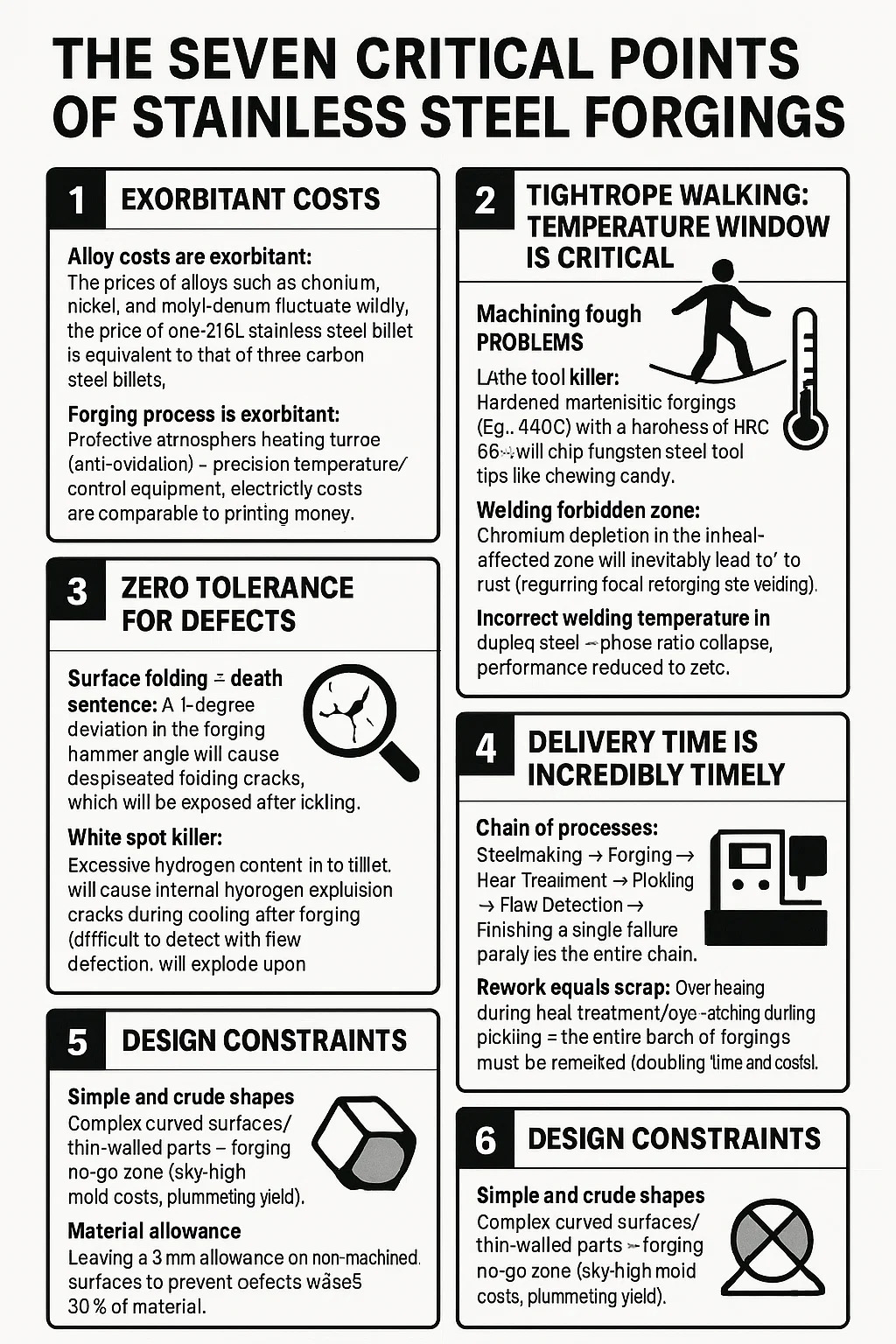

The Seven Critical Points of Stainless Steel Forgings

Content

1. Exorbitant Costs

Alloy costs are exorbitant: The prices of alloys such as chromium, nickel, and molybdenum fluctuate wildly; the price of one 316L stainless steel billet is equivalent to that of three carbon steel billets.

Forging Process is Exorbitant: Protective atmosphere heating furnace (anti-oxidation) + precision temperature control equipment; electricity costs are comparable to printing money.

2. Tightrope Walking: Temperature window is critical

Austenitic steel (304): 500-850℃ = death zone; exceeding this range by 1 minute = corrosion resistance halved.

Martensitic steel (420): Stop forging < 950℃ = instant cracking; slow forging will result in scrap.

Cooling Speed is critical:

Austenitic steel must be water-quenched to 500-800℃ (slow cooling = self-destruction of rust-proof armor).

Martensitic steel requires sand burial for slow cooling for 48 hours (rapid cooling = bursting into eight pieces).

3. Machining Tough Problems

Lathe Tool Killer: Hardened martensitic forgings (e.g., 440C) with a hardness of HRC 58+ will chip tungsten steel tool tips like chewing candy.

Welding Forbidden Zone: Chromium depletion in the heat-affected zone will inevitably lead to rust (requiring local reforging after welding).

Incorrect welding temperature in duplex steel = phase ratio collapse, performance reduced to zero.

4. Zero Tolerance for Defects

Surface Folding = Death Sentence: A 1-degree deviation in the forging hammer angle will cause deep-seated folding cracks, which will be exposed after pickling.

White Spot Killer: Excessive hydrogen content in the billet will cause internal hydrogen explosion cracks during cooling after forging (difficult to detect with flaw detection, will explode upon installation).

5. Delivery Time is Incredibly Timely

Chain of Processes: Steelmaking → Forging → Heat Treatment → Pickling → Flaw Detection → Finishing; a single failure paralyzes the entire chain.

Rework equals scrap: Overheating during heat treatment/over-etching during pickling = the entire batch of forgings must be remelted (doubling time and costs).

6. Design Constraints

Simple and crude shapes: Complex curved surfaces/thin-walled parts = forging no-go zone (sky-high mold costs, plummeting yield).

Material allowance: Leaving a 3mm allowance on non-machined surfaces to prevent defects wastes 30% of material.

英语

英语 德语

德语 阿拉伯语

阿拉伯语