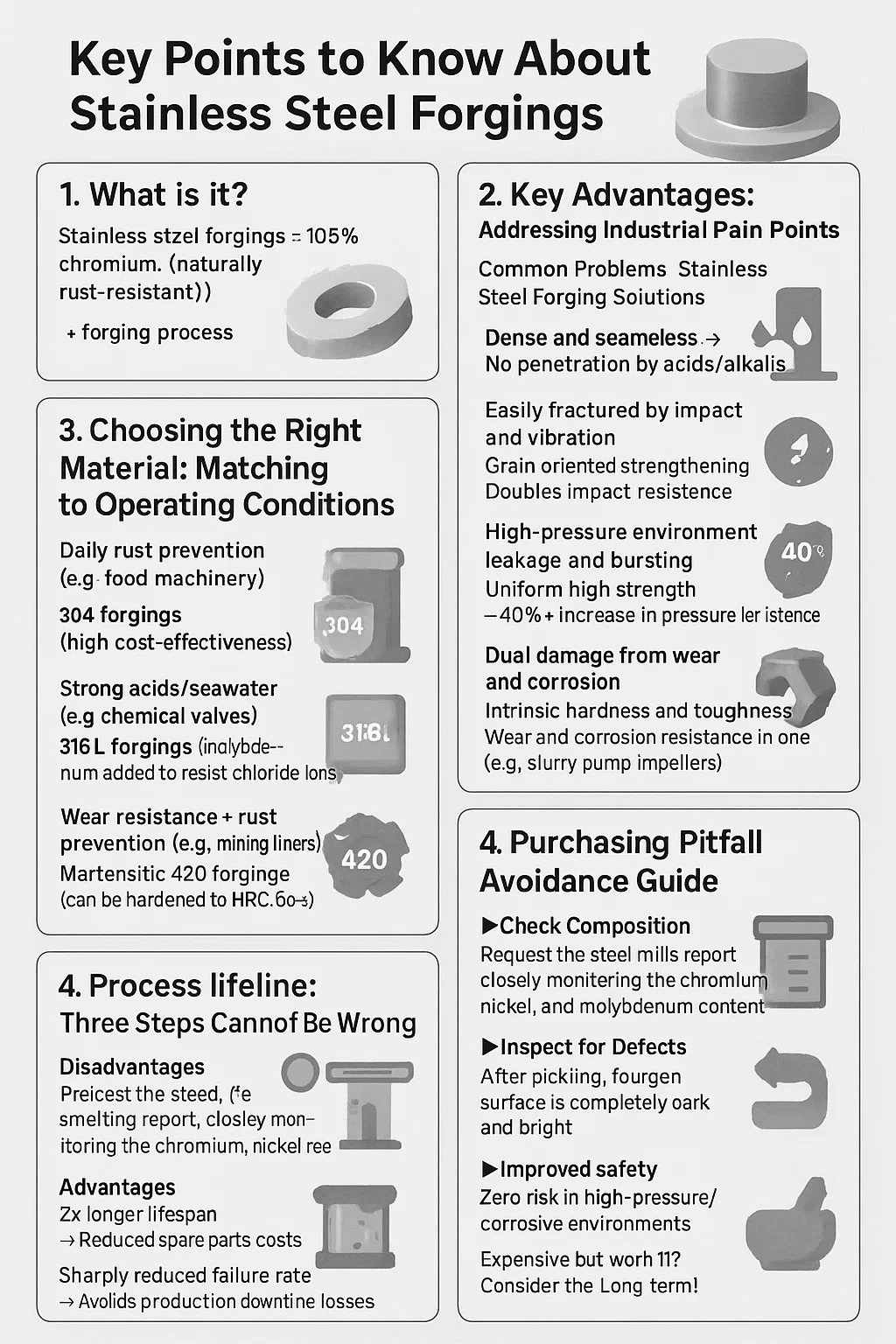

Key points to know about Stainless Steel Forgeds

Content

1. What is it?

Stainless steel forgings = Stainless steel (containing ≥10.5% chromium, naturally rust-resistant) + forging process (high-temperature hammering).

Core Values:

▶Denser than castings (forging eliminates porosity and cracks)

▶Stronger and tougher than machined parts (preserves metal flow lines)

2. Key Advantages: Addressing Industrial Pain Points

Common Problems: Stainless Steel Forging Solutions

Corrosion-induced perforation of parts: Dense and seamless → No penetration by acids/alkalis

Easily fractured by impact and vibration: Grain-oriented strengthening → Doubles impact resistance

High-pressure environment leakage and bursting: Uniform high strength → 40%+ increase in pressure resistance

Dual damage from wear and corrosion: Intrinsic hardness and toughness → Wear and corrosion resistance in one (e.g., slurry pump impellers)

3. Choosing the Right Material: Matching to Operating Conditions

Daily rust prevention (e.g., food machinery) → 304 forgings (high cost-effectiveness)

Strong acids/seawater (e.g., chemical valves) → 316L forgings (molybdenum added to resist chloride ions)

Wear resistance + rust prevention (e.g., mining liners) → Martensitic 420 forgings (can be hardened to HRC) 50+) High pressure + corrosion (e.g., submarine flanges) → Duplex 2205 forgings (strength + corrosion resistance dual improvement)

4. Process lifeline: Three steps cannot be wrong

▶Heating and temperature control:

304 steel must not be slowly cooled between 500-850℃ (otherwise rust resistance collapses)

Martensitic steel stopping forging temperature ≥950℃ (low-temperature forging will crack)

▶Post-forging cooling:

Austenitic steel (e.g., 316L) → rapid cooling water quenching (skipping the dangerous temperature zone)

Martensitic steel (e.g., 420) → sand immersion slow cooling (rapid cooling will inevitably crack)

▶Surface treatment:

Acid pickling and passivation are the soul! Forming a chromium oxide film doubles the rust resistance.

5. Purchasing Pitfall Avoidance Guide

▶Check Composition:

Request the steel mill's smelting report, closely monitoring the chromium, nickel, and molybdenum content (even a 0.5% reduction drastically reduces performance).

▶Inspect for Defects:

After pickling, the surface should be completely white and bright with no black spots (black spots indicate potential corrosion). Ultrasonic testing should show no defects larger than 2mm (essential for high-pressure components).

▶Check the Manufacturer:

Choose a supplier with capabilities covering the entire process from steelmaking to forging to heat treatment. Reject products without a permanent steel stamp (including grade/furnace number/batch number).

6. Expensive but Worth It? Consider the Long Term!

Disadvantages: Price 30%+ higher than castings, longer delivery time (at least 2 weeks).

Advantages:

▶2x longer lifespan → Reduced spare parts costs

▶Sharply reduced failure rate → Avoids production downtime losses

▶Improved safety → Zero risk in high-pressure/corrosive environments

英语

英语 德语

德语 阿拉伯语

阿拉伯语