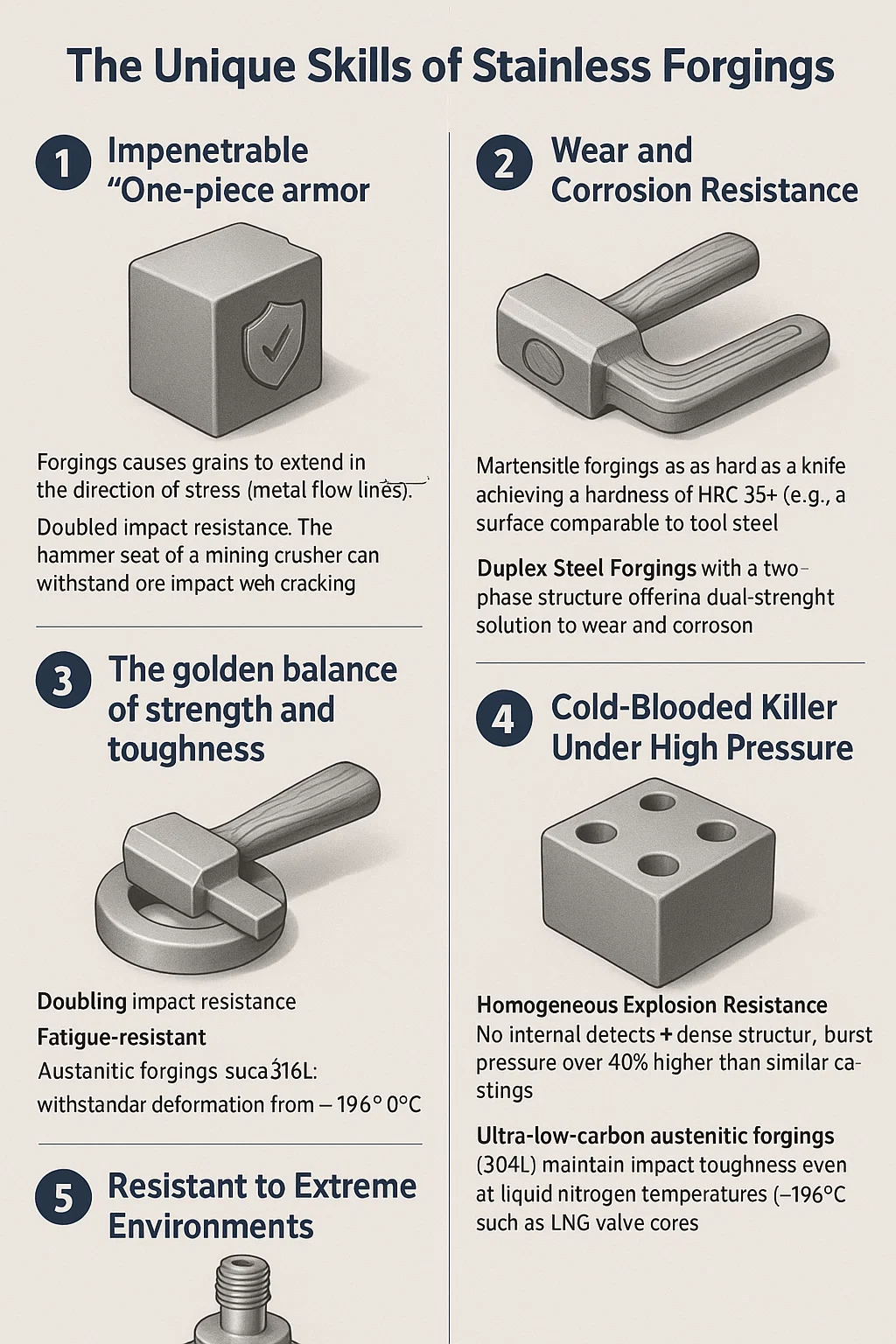

The unique skills of stainless steel forgings

1. Impenetrable "One-piece armor"

Unbreakable: Forging thoroughly compacts pores and shrinkage, leaving no room for corrosive media to enter—castings are like sponges, forgings are like solid ingots.

Grain boundary fortresses: Fine-grained structure and high-purity grain boundaries eliminate intergranular corrosion (a cancer of cast stainless steel).

2. The golden balance of strength and toughness

Strong and tough: Forging causes grains to extend in the direction of stress (metal flow lines), achieving:

Doubled impact resistance: The hammer seat of a mining crusher can withstand ore impact without cracking.

Fatigue-resistant: High-pressure valve stems can withstand tens of millions of cycles of pressure differentials without breaking.

Both rigidity and flexibility: Austenitic forgings (such as 316L) are incredibly tough, withstanding deformation from -196°C to 800°C.

3. Wear and Corrosion Resistance

Martensitic forgings are as hard as a knife: After quenching, they achieve a hardness of HRC 55+ (e.g., 440C), with a surface comparable to tool steel.

Mining Applications: Valve sealing surfaces conveying quartz slurry withstand abrasive scraping for ten years without leakage.

Duplex Steel Forgings: Chromium-molybdenum alloy with a two-phase structure, offering a dual-strength solution to wear and corrosion.

Mining Applications: Flotation machine agitator arms simultaneously resist sulfide corrosion and slurry erosion.

4. Cold-Blooded Killer Under High Pressure

Homogeneous Explosion Resistance: No internal defects + dense structure, burst pressure over 40% higher than similar castings.

The Lifeblood of Mining: 500 Bar forged valve blocks for coal mining hydraulic supports, with zero explosion incidents for ten years.

Stress Corrosion Immunity: Forging eliminates residual stress, resulting in no cracking in chloride/hydrogen sulfide environments.

5. Resistant to Extreme Environments

Red-hot, 1,000-degree heat: Chromium-nickel alloy steel forgings (such as 310S) maintain strength at temperatures up to 1100°C, specifically designed for hot-blast furnace components.

Absolutely resistant to extreme cold: Ultra-low-carbon austenitic forgings (304L) maintain impact toughness even at liquid nitrogen temperatures (-196°C), such as LNG valve cores.

英语

英语 德语

德语 阿拉伯语

阿拉伯语