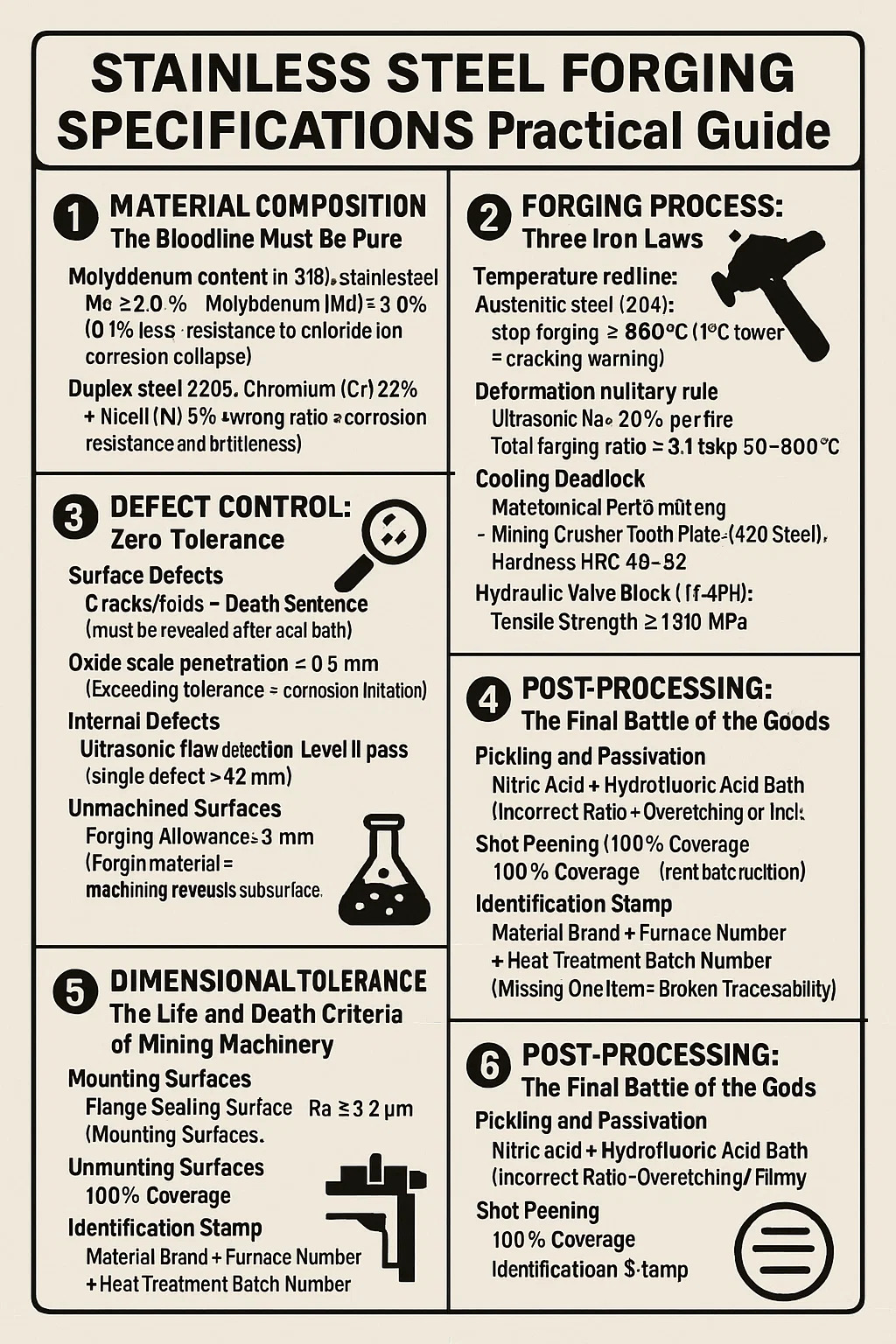

Stainless Steel Forging Specifications Practical Guide

Content

1. Material composition: The bloodline must be pure

Chromium, nickel and molybdenum content is stuck:

316L stainless steel: Molybdenum (Mo) ≥ 2.0% (0.1% less = resistance to chloride ion corrosion collapse).

Duplex steel 2205: Chromium (Cr) 22% + Nickel (Ni) 5% (wrong ratio = corrosion resistance and brittleness).

Carbon content is pressed to the limit: Ultra-low carbon steel (such as 304L) carbon ≤ 0.03% (0.01% more = double the risk of intergranular corrosion).

2. Forging process: three iron laws

Temperature red line:

Austenitic steel (304): stop forging ≥ 850℃ (1℃ lower = cracking warning).

Martensitic steel (420): heating ≤ 1180℃ (5℃ over = grain coarsening and scrap).

Deformation military rule:

Deformation ≥ 20% per fire (lazy small forging = core not compacted = corrosion risk).

Total forging ratio ≥ 3:1 (Insufficient forging = Residual as-cast structure = Reduced performance).

Cooling Deadlock:

Martensitic steel: Immediately enter a slow cooling pit after forging (air cooling = cracks).

Austenitic steel: Skip water quenching at 500-800°C (slow cooling = carbide precipitation = zero corrosion resistance).

3. Defect Control: Zero Tolerance

Surface Defects:

Cracks/folds = Death Sentence (must be revealed after acid bath).

Oxide scale penetration ≤ 0.5mm (Exceeding tolerance = corrosion initiation point).

Internal Defects:

Ultrasonic flaw detection Level II pass (single defect ≤ φ2mm = baseline for high-voltage mining parts).

White spots/hydrogen embrittlement = veto (forging internal bomb).

4. Performance Indicators: Practical Testing

Corrosion Resistance Must-Test:

Intergranular Corrosion Test (Boiled in sulfuric acid and copper sulfate for 24 hours): No cracks upon bending (one crack = entire batch rejection). Pitting Corrosion Potential (3.5% NaCl Solution): 316L ≥ 0.25V (low potential = premature failure in seawater conditions).

Mechanical Performance Deadline - Mechanical Performance Deadline:

Mining Crusher Tooth Plate (420 Steel): Hardness HRC 48-52 (low = wear, high = chipping).

Hydraulic Valve Block (17-4PH): Tensile Strength ≥ 1310 MPa (soft = high-pressure leakage, brittle = bursting).

5. Dimensional Tolerance: The Life and Death Criteria of Mining Machinery

Mounting Surfaces:

Flange Sealing Surface: Roughness Ra ≤ 3.2 μm (roughness = slurry leakage).

Shaft-Hole Fit: Tolerance h7/H7 (loose = vibration disengagement, tight = thermal expansion seizure).

Unmachined Surfaces:

Forging Allowance ≥ 3 mm (stingy material = machining reveals subsurface defects).

6. Post-Processing: The Final Battle of the Gods

Pickling and Passivation:

Nitric Acid + Hydrofluoric Acid Bath (Incorrect Ratio = Overetching or Incomplete Film) → Fully Passivated, Bright White Surface.

Shot Peening:

100% Coverage (Missed Shots = Fatigue Crack Initiation).

Identification Stamp:

Material Brand + Furnace Number + Heat Treatment Batch Number (Missing One Item = Broken Traceability = Prohibited).

英语

英语 德语

德语 阿拉伯语

阿拉伯语