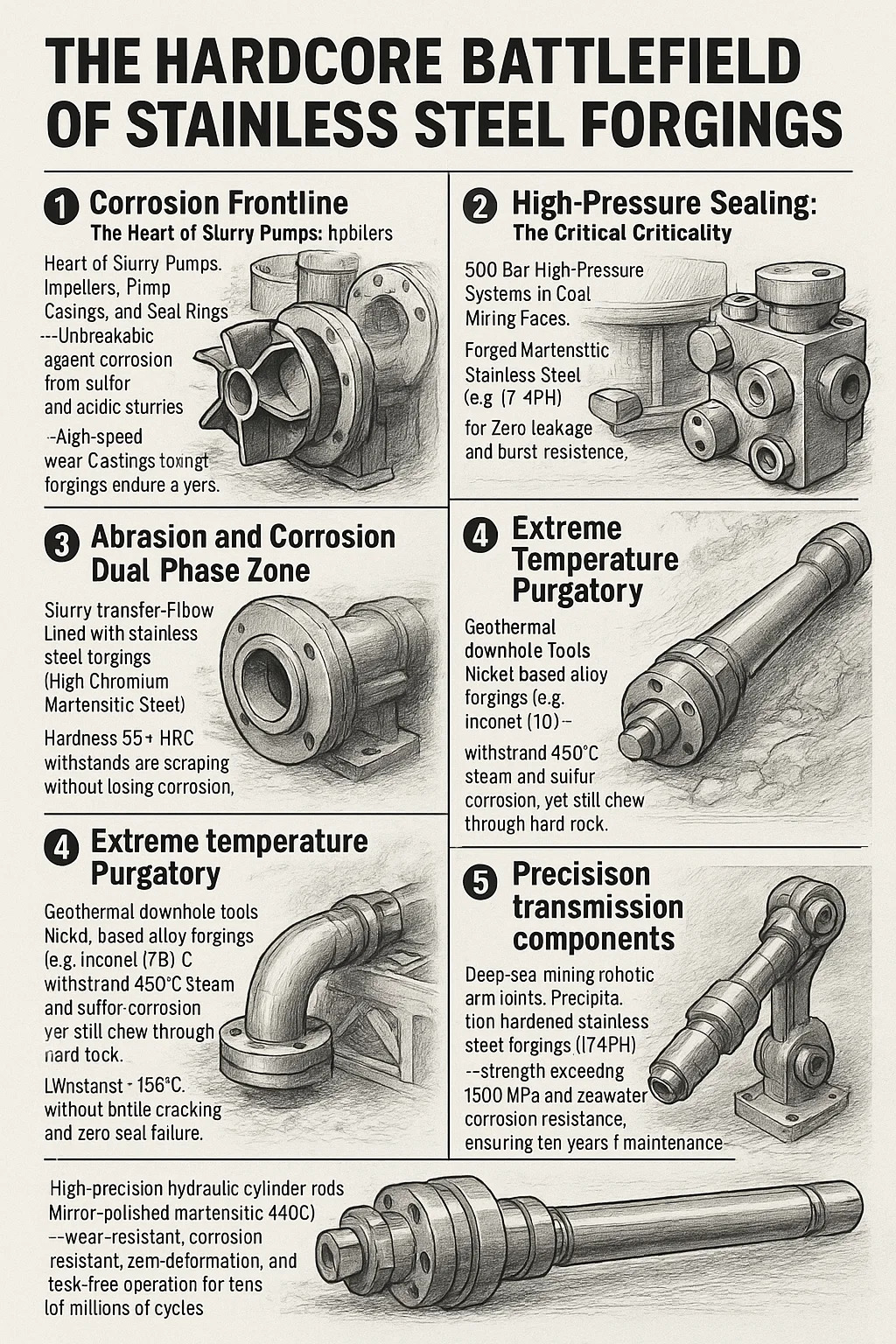

The Hardcore Battlefield of Stainless Steel Forgings

1. Corrosion Frontline

The Heart of Slurry Pumps: Impellers, Pump Casings, and Seal Rings—Unbreakable against corrosion from sulfur- and acidic slurries and high-speed wear. Castings wear out in six months, while forgings endure three years.

Corrosion Tanks in Processing Plants: Flotation Cell Agitator Shafts and Leaching Reactor Agitator Arms—Austenitic Forgings (316L) withstand acid and alkali conditions without breaking or perforating.

2. High-Pressure Sealing: The Critical Criticality

Hydraulic Support Valve Blocks: 500 Bar High-Pressure Systems in Coal Mining Faces—Forged Martensitic Stainless Steel (e.g., 17-4PH) for Zero Leakage and Burst Resistance.

Supercritical Pipe Flanges: Geothermal/Deep-Sea Mining High-Pressure Pipelines—Duplex Steel Forgings (2205)—Sealed to Close Corrosion Notches, Stable Under High Pressure.

3. Abrasion and Corrosion Dual-Phase Zone

Slurry Transfer Elbows: Lined with Stainless Steel Forgings (High-Chromium Martensitic Steel)—Hardness 55+ HRC, Withstands Ore Scraping Without Losing Corrosion. Ore-washing screen support: Duplex steel forged connectors – withstand sulfide corrosion and ore impact, requiring no replacement for ten years.

4. Extreme Temperature Purgatory

Geothermal downhole tools: Nickel-based alloy forgings (e.g., Inconel 718) – withstand 450°C steam and sulfur corrosion, yet still chew through hard rock.

LNG valve body: Ultra-low-temperature austenitic forgings (304L) – withstand -196°C without brittle cracking and zero seal failure.

5. Precision transmission components

Deep-sea mining robotic arm joints: Precipitation-hardened stainless steel forgings (17-4PH) – strength exceeding 1500 MPa and seawater corrosion resistance, ensuring ten years of maintenance-free joints.

High-precision hydraulic cylinder rods: Mirror-polished martensitic forgings (440C) – wear-resistant, corrosion-resistant, zero deformation, and leak-free operation for tens of millions of cycles.

英语

英语 德语

德语 阿拉伯语

阿拉伯语