Content

Direct Answer: Which Method is More Cost-Effective?

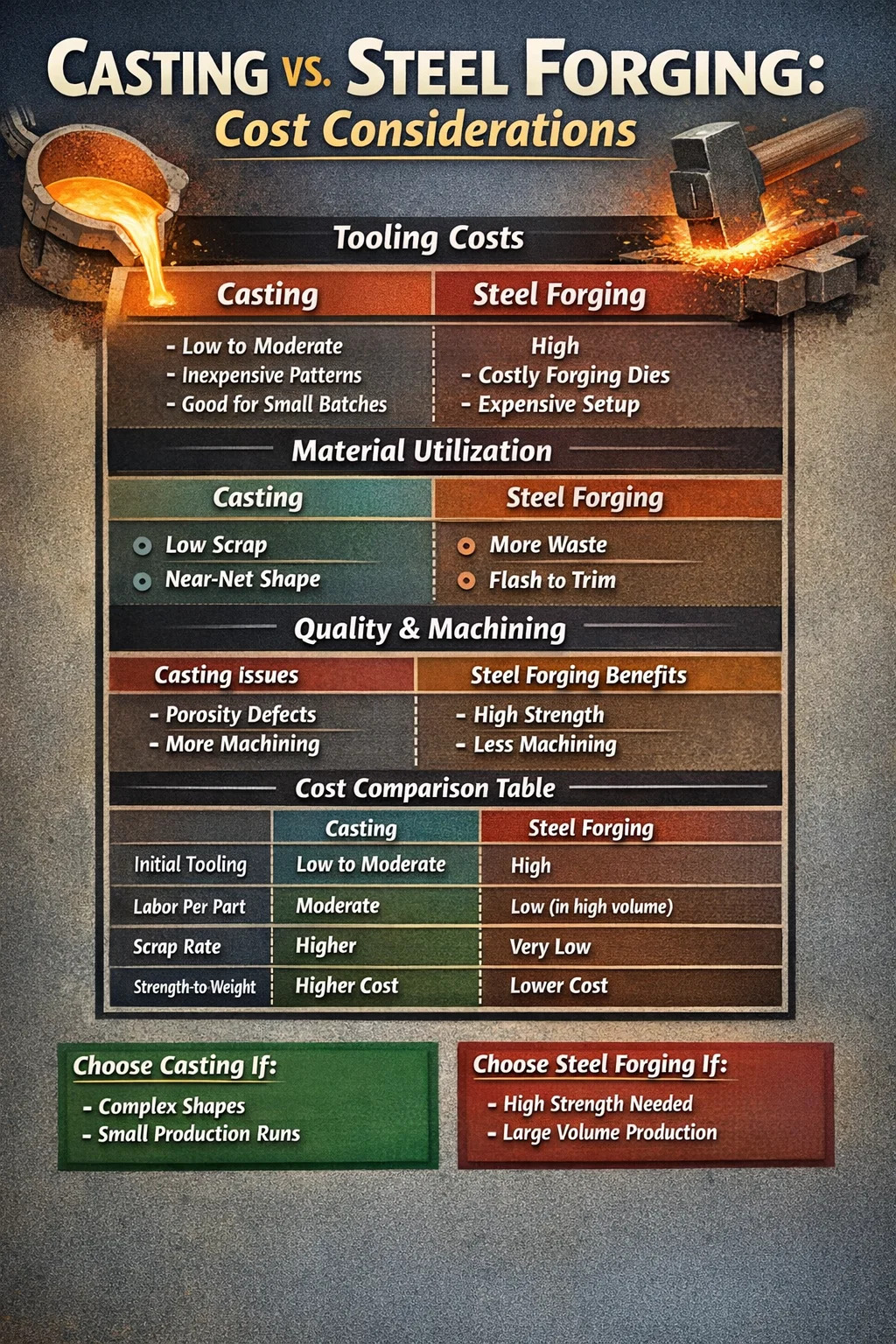

In the short term and for simple, high-volume production of complex shapes, casting is generally cheaper regarding initial unit price. However, steel forging often proves more economical over the long term for parts that require high strength, minimal defects, and long service lives. The "cheapest" option depends entirely on production volume, geometry complexity, and secondary machining requirements.

The Initial Investment: Tooling and Setup Costs

Budgeting for a new project begins with tooling. Casting and forging have vastly different entry costs that dictate which method a purchasing manager might choose.

Casting Tooling Costs

Sand casting has relatively low tooling costs because the patterns can be made from wood or plastic. Investment casting (lost wax) is more expensive due to the precision dies required. Generally, casting allows for lower upfront capital for prototypes and small batches.

Steel Forging Tooling Costs

Forging dies must withstand massive pressures and high temperatures. These dies are made from high-grade tool steel and are significantly more expensive than casting patterns. If you are only producing 50 to 100 pieces, the "per-part" tooling cost for forging may be prohibitively high compared to casting.

Material Utilization and Waste Reduction

Raw material prices significantly impact the total invoice. How each process handles the metal determines the "buy-to-fly" ratio.

Casting allows for "near-net-shape" production. Because liquid metal fills every crevice of a mold, there is very little scrap. This makes casting cheaper when using expensive alloys. In contrast, steel forging often results in "flash"—excess metal squeezed out between the dies—which must be trimmed and recycled. However, for standard carbon steel, the cost of this waste is often offset by the superior speed of forging hammers.

The Hidden Costs: Machining and Quality Control

Price isn't just about the part that leaves the mold or hammer; it is about the finished product ready for assembly.

- Porosity Issues: Castings frequently suffer from internal gas bubbles or shrinkage. This leads to a higher "rejection rate" during X-ray inspection. If 10% of your castings are scrapped after machining, the "cheap" casting becomes very expensive.

- Structural Integrity: A steel forging is virtually always free of internal voids. The forging process actually heals internal flaws, meaning you pay for 100 useful parts when you order 100.

- Machining Time: While casting produces complex shapes easily, forged parts are often tougher and more uniform. Forging dies can produce excellent surface finishes that might eliminate the need for certain grinding stages, saving labor costs.

Cost Comparison Table by Factor

| Cost Factor | Casting | Steel Forging |

|---|---|---|

| Initial Tooling | Low to Moderate | High |

| Labor Per Part | Moderate | Low (in high volume) |

| Scrap Rate | Higher (due to defects) | Very Low |

| Strength-to-Weight Cost | Higher (needs more metal) | Lower (less metal needed) |

Volume: The Ultimate Cost Decider

Economy of scale is the most powerful force in manufacturing costs. Forging machines are incredibly fast once the setup is complete. For example, an automated steel forging line can produce thousands of connecting rods in a single shift with minimal human intervention. In these massive volumes, the high cost of the dies is spread so thin that the unit price drops below that of casting.

Conversely, if you only need 10 pieces of a complex pump housing, casting is the logical choice. You avoid the five-figure die cost and accept a slightly higher per-unit machining cost because the total project cost remains lower.

Summary of Practical Advice

To choose the cheapest path, evaluate your project based on these criteria:

- Choose Casting if: The shape is incredibly complex (internal cavities), the material is hard to forge (like certain cast irons), or the production run is small.

- Choose Steel Forging if: The part is safety-critical, high strength is required, production runs are large, or you want to minimize long-term liability and replacement costs.

英语

英语 德语

德语 阿拉伯语

阿拉伯语