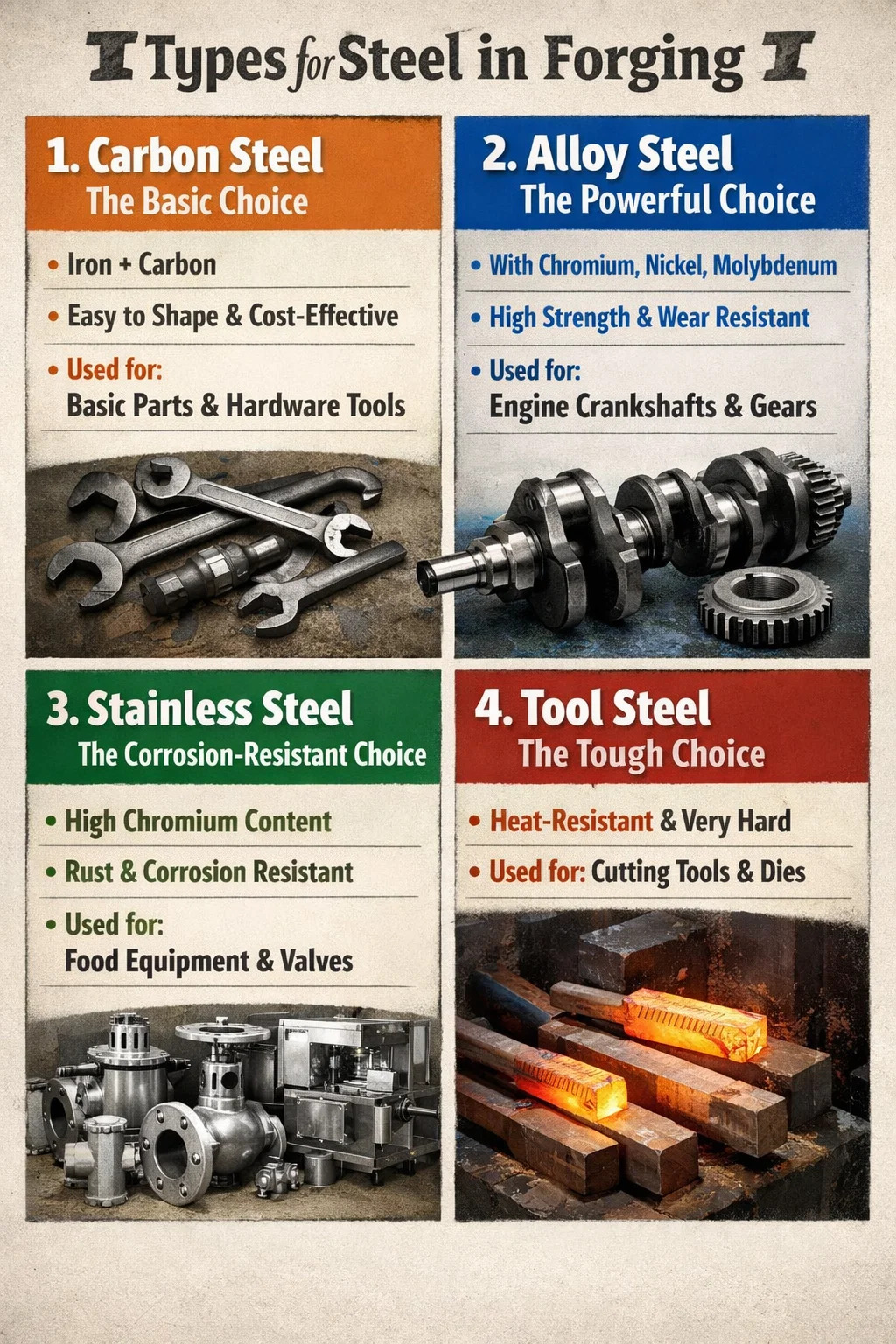

In actual industrial production, not all steel is suitable for "heating and hammering." To ensure that the resulting parts are both strong and durable, steel forging typically uses the following mainstream types of steel, depending on the application:

Content

1. Carbon Steel (The Basic Choice)

Common definition: This is the purest and most common type of steel, mainly a combination of iron and carbon.

Characteristics: It is relatively easy to work with; it changes shape easily after heating, making forging relatively simple.

Applications: This type of steel is widely used in the manufacture of everyday parts, such as ordinary connectors, simple levers, or hardware tools that don't require extremely demanding craftsmanship. Its advantage lies in its low cost and high cost-effectiveness.

2. Alloy Steel (The Powerful Choice)

Common definition: Based on ordinary steel, specific metal elements such as chromium, nickel, and molybdenum are added, like giving the steel "armor."

Characteristics: Although this type of steel is harder and more difficult to work with during the steel forging process, its strength, hardness, and wear resistance are significantly improved after forming.

Applications: Specifically designed for demanding tasks. For example, automobile engine crankshafts, gearbox gears, or mining machinery parts that need to withstand huge impact forces.

3. Stainless Steel (The Corrosion-Resistant Choice)

Common definition: This type of steel contains a large amount of chromium, and its greatest advantage is that it is "not afraid of water or rust."

Characteristics: It has good toughness, but it is quite sensitive to temperature. Forging stainless steel requires very precise temperature control, otherwise, it is prone to cracking.

Applications: Commonly found in food processing machinery and medical equipment that require extremely high hygiene standards, or valves and pump bodies that frequently come into contact with seawater and chemicals.

4. Tool Steel (The Tough Choice)

Common definition: As the name suggests, this type of steel is specifically used to manufacture "tools," such as various cutting tools and molds.

Characteristics: It is extremely heat-resistant; even when working at high temperatures and glowing red, it can still maintain high hardness and will not soften. Applications: It's a "tough nut to crack" in the forging industry, and is typically used to make durable parts that need to cut or stamp other metals.

英语

英语 德语

德语 阿拉伯语

阿拉伯语