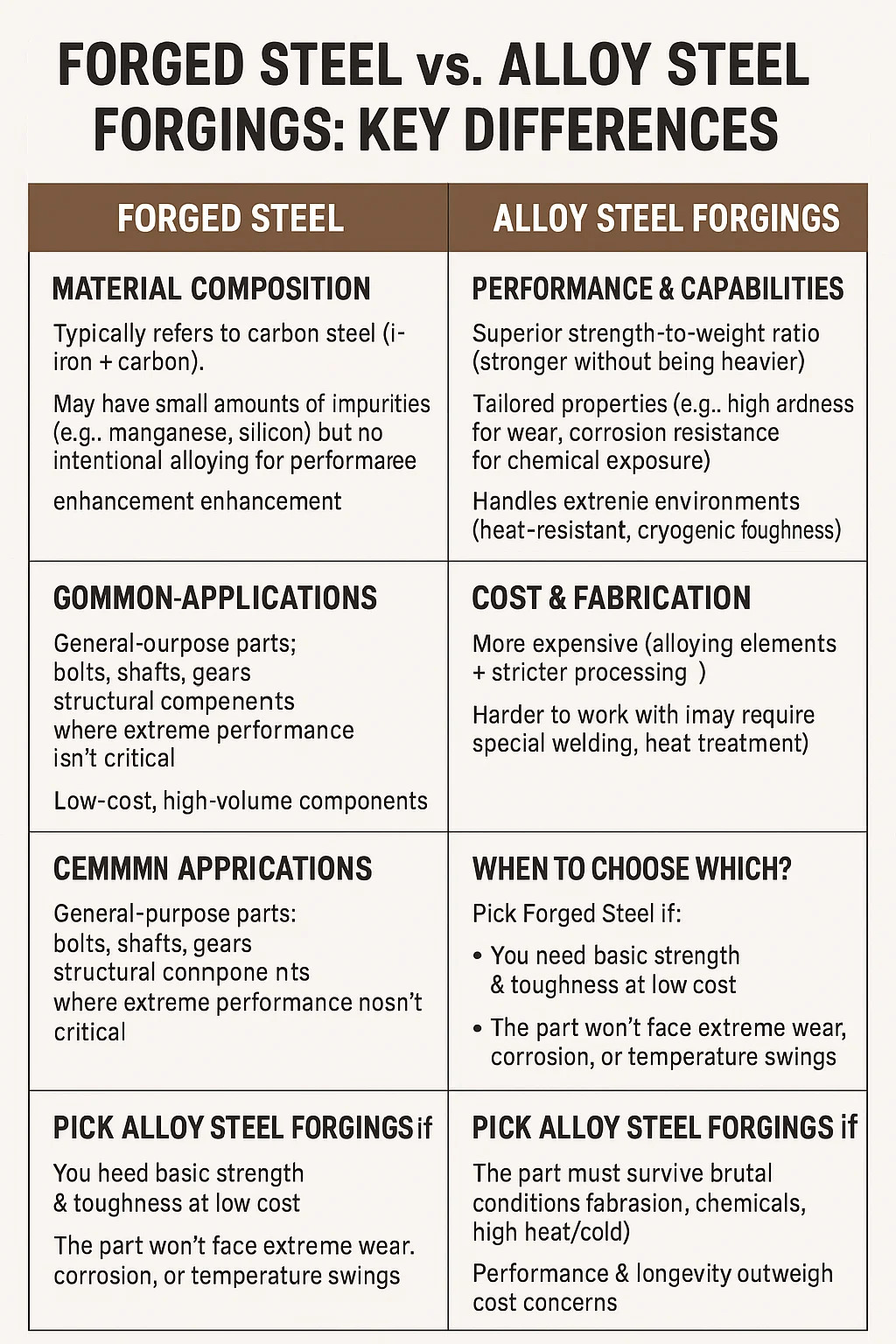

Forged Steel vs. Alloy Steel Forgings: Key Differences

1. Material Composition

Forged Steel: Typically refers to carbon steel (iron + carbon). May have small amounts of impurities (e.g., manganese, silicon) but no intentional alloying for performance enhancement.

Alloy Steel Forgings: Deliberately mixed with alloying elements (e.g., chromium, nickel, molybdenum, vanadium) to boost strength, hardness, corrosion resistance, or heat resistance.

2. Performance & Capabilities

Forged Steel:

Good strength & toughness (better than cast steel).

Limited wear/corrosion resistance – wears out faster in harsh conditions.

Weaker at extreme temps (softens at high heat, brittle in deep cold).

Alloy Steel Forgings:

Superior strength-to-weight ratio (stronger without being heavier).

Tailored properties (e.g., high hardness for wear, corrosion resistance for chemical exposure).

Handles extreme environments (heat-resistant, cryogenic toughness, etc.).

3. Common Applications

Forged Steel:

General-purpose parts: bolts, shafts, gears, structural components where extreme performance isn’t critical.

Low-cost, high-volume components.

Alloy Steel Forgings:

Heavy-duty & specialized uses: Crusher hammers, mining drill bits, turbine blades, high-pressure valves, aerospace components.

Where wear, corrosion, or extreme temps would destroy standard forged steel.

4. Cost & Fabrication

Forged Steel:

Cheaper (no expensive alloying elements).

Easier to machine & weld (less risk of cracking or hardening issues).

Alloy Steel Forgings:

More expensive (alloying elements + stricter processing).

Harder to work with (may require special welding, heat treatment).

5. When to Choose Which?

Pick Forged Steel if:

You need basic strength & toughness at low cost.

The part won't face extreme wear, corrosion, or temperature swings.

Pick Alloy Steel Forgings if:

The part must survive brutal conditions (abrasion, chemicals, high heat/cold).

Performance & longevity outweigh cost concerns.

英语

英语 德语

德语 阿拉伯语

阿拉伯语