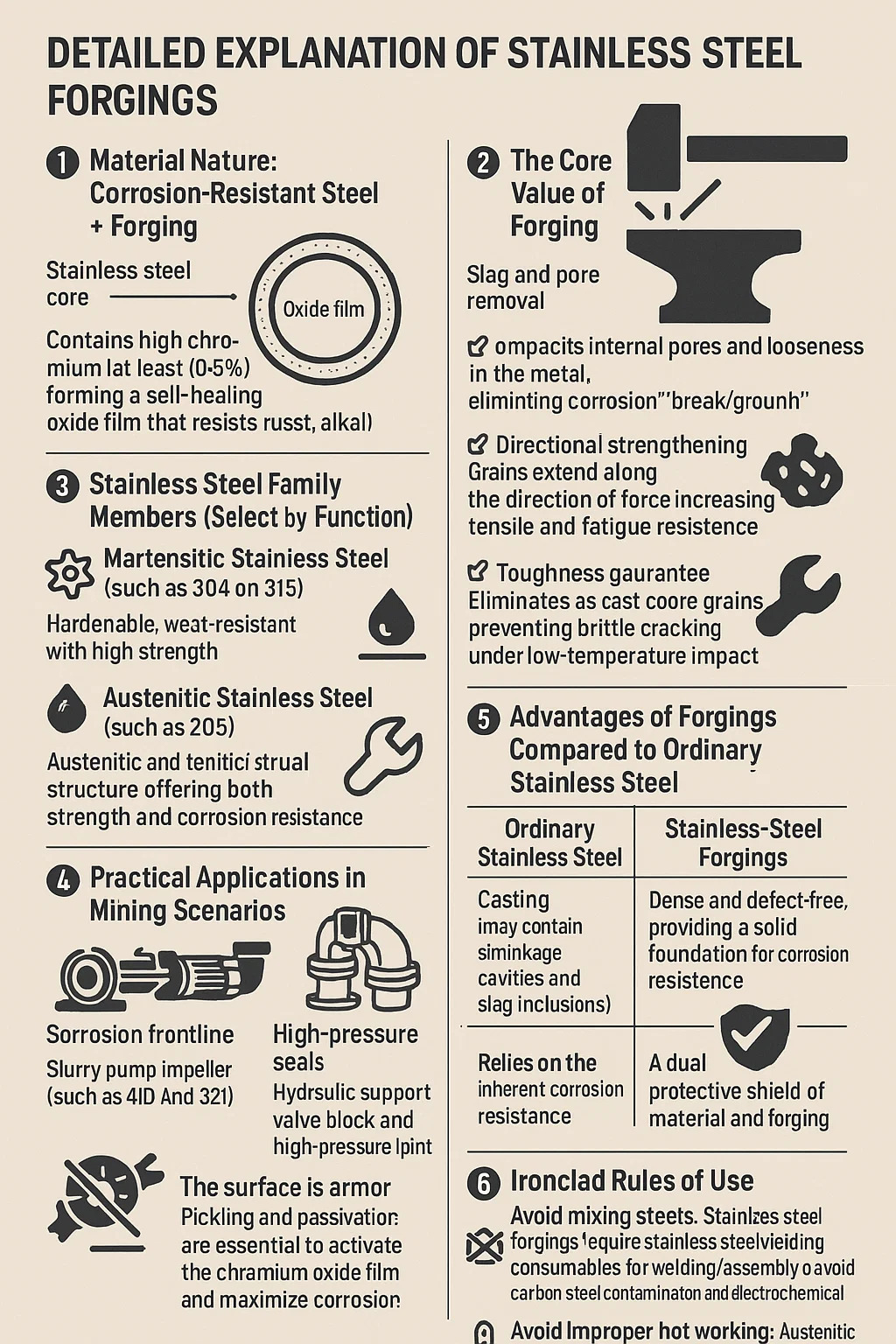

Detailed Explanation of Stainless Steel Forgings

1. Material Nature: Corrosion-Resistant Steel + Forging

Stainless Steel Core: Contains high chromium (at least 10.5%), forming a self-healing oxide film that resists rust, acid, and alkali.

Forging Process: High-temperature, high-pressure hammering, not casting or machining.

2. The Core Value of Forging

Slag and Pore Removal: Forging compacts internal pores and looseness in the metal, eliminating corrosion "breakthroughs."

Directional Strengthening: Grains extend along the direction of force, increasing tensile and fatigue resistance.

Toughness Guarantee: Eliminates as-cast coarse grains, preventing brittle cracking under low-temperature impact.

3. Stainless Steel Family Members (Select by Function)

--Martensitic Stainless Steel (such as 410 and 420):

Hardenable, wear-resistant and scratch-resistant, with high strength.

Weaknesses: Welds easily crack, and corrosion resistance is inferior to its counterparts.

Mining Applications: Components requiring wear resistance and mild corrosion protection (such as mining valve cores and wear-resistant bushings).

--Austenitic stainless steel (such as 304 and 316):

Ace in corrosion resistance (316 is particularly resistant to chloride ion corrosion).

Excellent toughness and resistance to magnetization, but relatively low hardness.

Mining applications: Slurry pump bodies, acid leaching tank agitator shafts, and seawater beneficiation pipeline flanges.

--Duplex stainless steel (such as 2205):

Austenitic and ferritic dual structure, offering both strength and corrosion resistance.

Excellent at resisting stress corrosion cracking.

Mining applications: High-pressure slurry valves and bolts for highly corrosive environments.

4. Practical Applications in Mining Scenarios

Corrosion Frontline:

Slurry pump impellers and pump casings (wear and acid and alkali resistance).

Flotation machine agitator shafts and blades (sulfide corrosion resistance).

High-pressure seals:

Hydraulic support valve blocks and high-pressure joints (strength, corrosion resistance, and leak prevention).

Abrasion and corrosion dual-kill zone:

Elbows in pipelines containing solid particles (lined with stainless steel forgings).

5. Advantages of Rolling Compared to Ordinary Stainless Steel

Ordinary Stainless Steel Stainless Steel Forgings

Casting (may contain shrinkage cavities and slag inclusions) Dense and defect-free, providing a solid foundation for corrosion resistance

Machining (cuts grain flow lines) Directed grain reinforcement, offering impact and fatigue resistance

Relies on the inherent corrosion resistance of the material: A dual protective shield of material and forging

6. Ironclad Rules of Use

Avoid mixing steels: Stainless steel forgings require stainless steel welding consumables for welding/assembly to avoid carbon steel contamination and electrochemical corrosion.

Avoid improper hot working: Austenitic stainless steel exposed to sensitive temperatures (450-850°C) for extended periods can degrade its corrosion resistance.

The surface is armor: Pickling and passivation are essential to activate the chromium oxide film and maximize corrosion resistance.

英语

英语 德语

德语 阿拉伯语

阿拉伯语