This is a very classic question. The simple and direct answer is: in most high-stress and critical applications, forging is indeed stronger and more reliable than welding.

Content

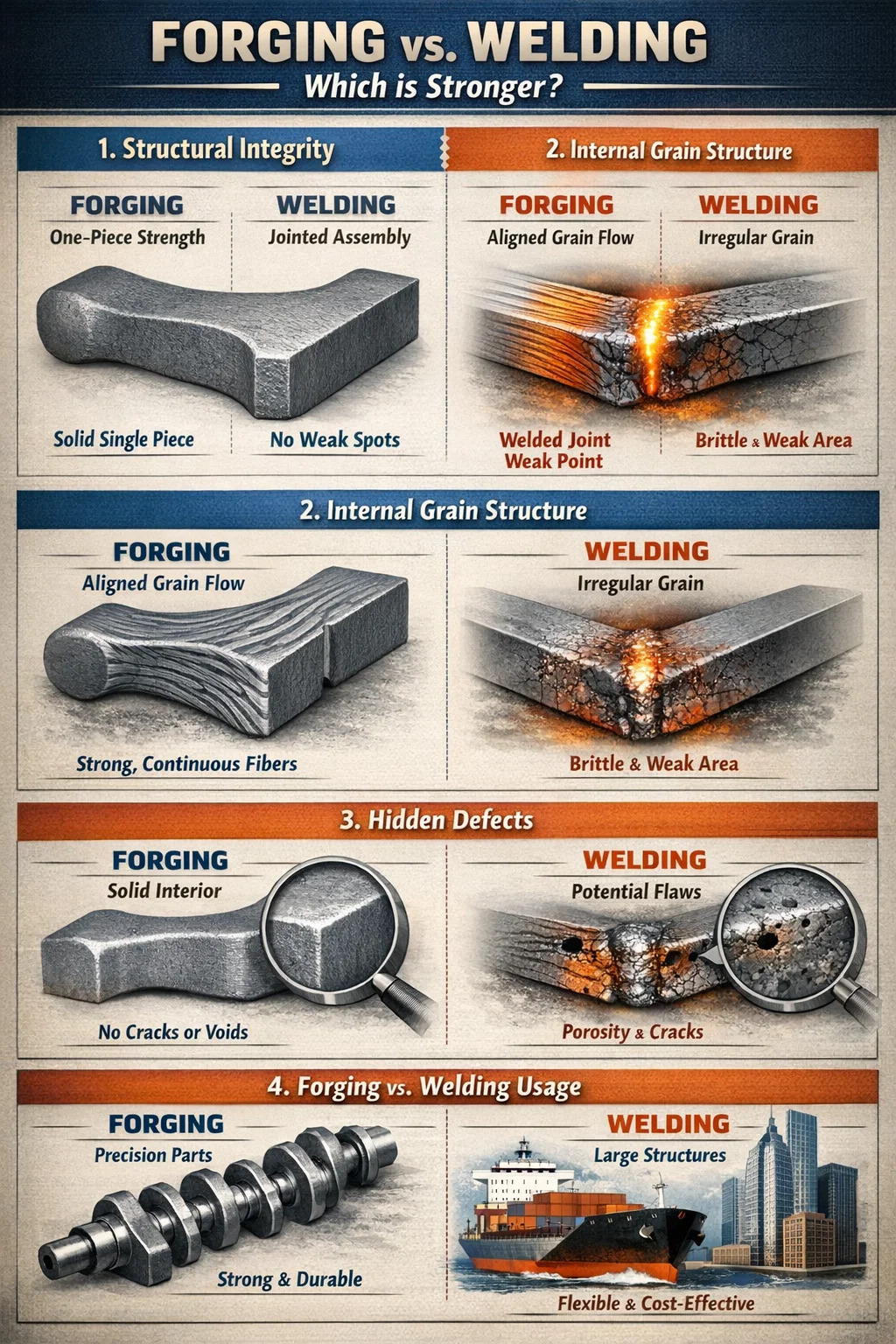

1. Structural Integrity: One-piece molding vs. strong assembly

Steel forging: It's like repeatedly kneading a large piece of dough and finally shaping it into a single whole. It's a complete entity with no breaks or seams inside. Because it's formed in one piece, it has no "weak points" when subjected to huge impacts or tensile forces.

Welding: It's like gluing two separate building blocks together with strong glue. Although modern welding technology is very advanced, it is still composed of two or more parts. The weld seam (the connection point) is always the area that requires the most attention in the entire part, and if not done properly, it can become the most easily broken "wound."

2. The direction of internal "muscles" (texture differences)

Forging's "muscles": When we perform steel forging, the internal crystal structure of the metal (you can imagine it as the muscle fibers of the metal) flows and aligns along the shape of the part. This is like the grain of wood; it's difficult to split wood against the grain, and forged parts become extremely tough because of this continuous "fiber flow."

Welding's "muscles": During welding, the metal at the weld seam is melted and then solidified, and the "muscle fibers" there are chaotic and disorganized. Moreover, due to the localized high temperature, the original metal next to the weld seam is also affected, becoming weaker or more brittle than other areas.

3. Potential Hidden Dangers: Visible strength vs. invisible concerns

Forged parts: Because they are formed by powerful compression, the metal inside is very solid, with almost no pores or cracks. These steel forging products have very high reliability when they leave the factory.

Welded parts: During the welding process, if there is even a slight tremor or the environment is humid, tiny bubbles (pores) or areas that haven't fully fused may form inside the weld seam. These tiny hidden dangers are hidden inside the metal and are not visible under normal circumstances, but once subjected to violent vibration or extreme pressure, they may start to crack from these small defects.

4. Why not use forging for everything?

Since forging produces stronger results, why bother with welding?

Flexibility: Welding is like building with LEGOs; you can assemble various oddly shaped steel plates into a massive framework (such as for shipbuilding or constructing skyscrapers). These colossal structures are difficult to forge as a single piece in a forging machine.

Cost: Welding is suitable for large and complex structures, while forging is better suited for precise and strong components.

英语

英语 德语

德语 阿拉伯语

阿拉伯语