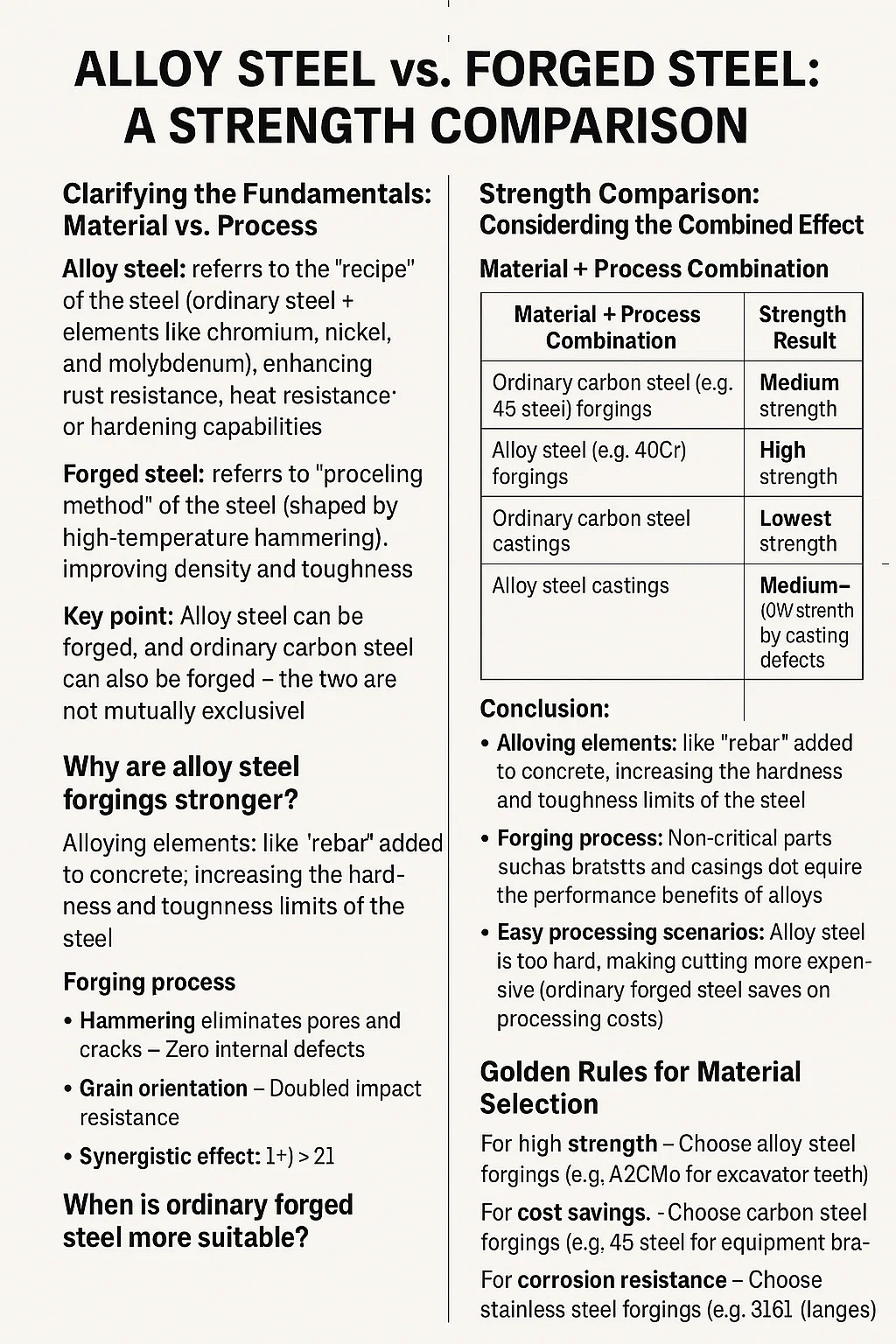

Alloy Steel vs. Forged Steel: A Strength Comparison

1. Clarifying the Fundamentals: Material vs. Process

Alloy steel: Refers to the "recipe" of the steel (ordinary steel + elements like chromium, nickel, and molybdenum), enhancing rust resistance, heat resistance, or hardening capabilities.

Forged steel: Refers to the "processing method" of the steel (shaped by high-temperature hammering), improving density and toughness.

Key point: Alloy steel can be forged, and ordinary carbon steel can also be forged – the two are not mutually exclusive!

2. Strength Comparison: Considering the Combined Effect

| Material & Process | Strength Outcome | Practical Implication |

|---|---|---|

| Plain Carbon Steel Forgings(e.g., AISI 1045) | Moderate StrengthAdequate for non-critical components | Handles standard loads but wears faster in abrasive environments |

| Alloy Steel Forgings(e.g., 4140, 4340) | High Strength/ToughnessSuperior wear/impact resistance | Withstands extreme stress in mining crushers & excavator joints |

| Plain Carbon Steel Castings(e.g., ASTM A27) | Lowest StrengthInternal defects compromise integrity | Prone to sudden fracture under cyclic loading |

| Alloy Steel Castings(e.g., 8630 cast) | Medium-Low StrengthAlloy benefits diluted by casting flaws | Better corrosion resistance but unreliable for high-pressure systems |

Conclusion:

▸ Alloy steel forgings = Alloy composition + Forging compaction → King of strength (e.g., mining gears)

▸ Discussing alloys without considering the process ≈ Theoretical discussion only (cast alloy steel may not be as strong as forged carbon steel)

3. Why are alloy steel forgings stronger?

Alloying elements: Like "rebar" added to concrete, increasing the hardness and toughness limits of the steel.

Forging process:

Hammering eliminates pores and cracks → Zero internal defects.

Grain orientation → Doubled impact resistance. Synergistic effect: 1+1 > 2!

4. When is ordinary forged steel more suitable?

Cost-effectiveness is a priority: Ordinary carbon steel forgings (e.g., Q235) are 30%+ cheaper than alloy forgings.

No extreme demands: Non-critical parts such as brackets and casings do not require the performance benefits of alloys.

Easy processing scenarios: Alloy steel is too hard, making cutting more expensive (ordinary forged steel saves on processing costs).

5. Golden Rules for Material Selection

For high strength → Choose **alloy steel forgings** (e.g., 42CrMo for excavator teeth)

For cost savings → Choose **carbon steel forgings** (e.g., 45 steel for equipment brackets)

For corrosion resistance → Choose **stainless steel forgings** (e.g., 316L flanges)

英语

英语 德语

德语 阿拉伯语

阿拉伯语